Modern Company For New Industries is an Egyptian industrial chemical company dedicated to manufacture of Sodium and Potassium Silicate with high quality that make them suitable for being used in great number of industrial sectors such as detergents, welding electrodes, waste water treatment and painting

Main Source of Pollution:

Dust emissions (TSP & PM10) inside work environment due to the manual a feeding of raw materials (Sodium carbonate & Silica) to the melting furnaces.

Environmental compliance Implemented Options

Automatic feeding and dosing system

Environmental and Economic Benefits

Environmental benefits:

Investment Cost: 2,650,000 L.E.

Economic Returns: 559,842 L.E per year.

Return Period: 4 Years.

The company is a medium size enterprise located in 10th of Ramadan industrial city. It produces suitable containers to local market and exportation in fields of fertilizers, chemicals and detergents. The company consumes in average about 650 to 700 ton/year from HDPE in addition to PP, PS and master patch.

Main Source of Pollution:

The main sources for solid waste generation are the finishing step and the off specification products. In certain types of containers the solid waste generated after finishing reaches a ratio of 43% by weight from the product.

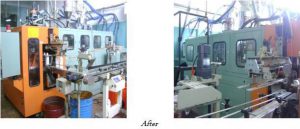

Environmental compliance Implemented Options

Recycling of the solid waste generated in the production of multi layers chemical resistance containers with a mixing ratio 2:1 between the recycled and the 1st grade PE respectively.

Environmental and Economic Benefits

Environmental benefits:

Investment Cost: 1,900,000 L.E.

Economic Returns: 1,150,000 L.E per year.

Return Period: 21 months.

Chloride Egypt manufactures several types and models of batteries. The company has production facilities for the whole production cycle: Lead oxide paste production, plate charging, acid filling and assembling. Chloride Egypt employs 450 employees working three shifts, five days/week.

Environmental compliance Implemented Options

Environmental and Economic Benefits

| Options | Environmental benefits | Economic saving / year (EGP) | Investment t/(EGP) | Pay-back period (months) |

|---|---|---|---|---|

| Acid vapours extraction and collecting system | Sulphuric acid reduction: 51.2 t/year Water consumption reduction: 3210 m3/year |

283,000 | 1,050,000 | 45 |

| Automatic sulphuric acid dosing system | Sulphuric acid reduction: 37.1 t/year | 53,000 | 110,000 | 25 |

| Controlled grid casting process | CO2 reduction: 114,000 t/year SO2 reduction: 7 t/year Heavy metals reduction: 2 kg/year PM10 reduction: 96 kg/year |

152,000 | 649,000 | 51 |

| Dust collector for the cutting and enveloping area | Heavy metal reduction: 18 t/year Regeneration of lead: 5 t/year |

122,000 | 303,000 | 30 |

| WWTP | Heavy metals reduction: 290 kg/year COD reduction: 9 t/year |

111,000 | 692,000 | 75 |

| Total | 721,000 | 2,804,000 | 47 |

Should you have any queries .. We are here to help

Contact us